Upscaling the NOVA technology with a large capacity prototype

Following a successful first year of testing and optimising the NOVA process on printed circuit board assemblies (PCBAs) from liquid crystal display TVs (LCD TVs) and cathode-ray TVs (CRT TVs), an upgraded and upscaled prototype has been pre-designed and will be manufactured in the upcoming months. While the current pilot is able to process up to 15 kg of low and mid-grade PCBAs by batch, this new prototype will boast a maximum capacity of 400 kg per batch.

The results obtained thus far are highly encouraging. Overall, from the LCD TVs to the precious metal concentrate that will be delivered to the next partners for refining, remarkable concentration rates have been achieved: gold (Au) has displayed a concentration factor exceeding 60, while silver (Ag) and palladium (Pd) exhibit concentration factors of 45 and 29, respectively. Furthermore, the recovery rates of these metals in valorised products surpassed 85%, with Au achieving an impressive recovery rate of 97,5%.

Electrodynamic fragmentation (EDF), attrition and froth flotation as concentration methods for end of life (EoL) autocatalysts

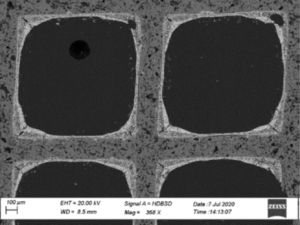

Given its ability to favour fragmentation of the material at the border between two different materials, electrodynamic fragmentation (EDF) has been used as an alternative to traditional grinding to selectively detach the PGM-rich washcoat from the cordierite matrix of EoL autocatalysts. While a significant part of PGMs was recovered in the obtained fine fraction, an additional step of attrition allowed to further improve the amount of PGMs collected.

- Selfrag machine used for electrodynamic fragmentation (EDF)

- Microscopic view of autocatalyst with cordierite structure and coated washcoat

Numerous combinations of technology (forth flotation, electrodynamic fragmentation, attrition) were tested with multiple stages and parameters, showing that the best recoveries were achieved with a traditional grinding steps and two flotation stages (a collectorless stage taking advantage of the natural hydrophobicity of the washcoat and a collector based flotation targeting the remaining washcoat). PGMs recovery rates displayed are in the range of 75% to 90%.

While recovery rates may currently fall short of meeting industrial requirements, electrodynamic fragmentation has demonstrated its impact on downstream hydrometallurgical processes and ULI will continue investigating this impact to determine if improved leaching performances can be obtained through this route.

Related article: Testing innovative technologies to optimise and upscale the concentration stage

This

project has received funding from the European Union’s

Horizon 2020 research and innovation programme under grant

agreement No 958302.

This

project has received funding from the European Union’s

Horizon 2020 research and innovation programme under grant

agreement No 958302.