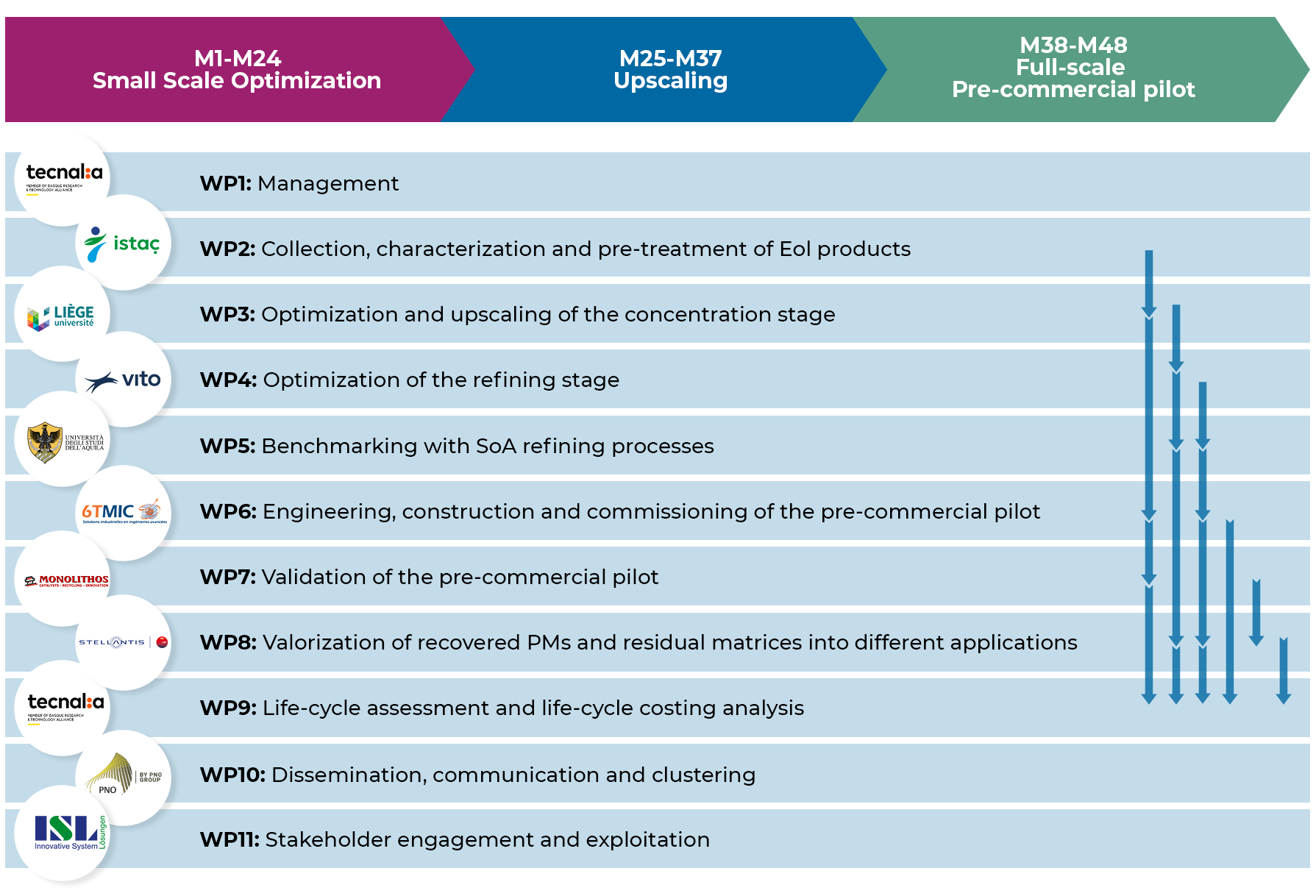

The PEACOC’s implementation plan has 11 work packages (WP), following the general structure below:

WP1: Management

Lead by TECNALIA, this work package will aim to develop an effective, transparent and comprehensive administrative, financial and legal management framework. Thus, ensuring the successful strategic and operational execution of the project framework. Furthermore, it will work towards a smooth collaboration and integration between all partners, as well as facilitating communication within the project consortium and the representatives of the European Commission.

WP2: Collection, characterization and pre-treatment of end-of-life products

ISTAC will lead WP2 that is designed to perform a material flow analysis and identify untapped end-of- life products that contains precious metals. Firstly, it will set the foundation of a new-massive scaled collection to supply significant volumes of end-of-life autocatalysis, PCBA and photovoltaic panels. Secondly, it will set up the collection and pre-treatment conditions of end-of-life products and supply the needed quantities to the partners. Finally, it will carry out a detailed characterization of the 3 different supplied materials.

WP3: Optimization and upscaling of the concentration stage

As part of WP3, ULiège will lead the concentration of Platinum Group Metals, gold, silver, tin and copper from Printed Circuit Board Assemblies, important components of Waste Electric and Electronic Equipment. Moreover, the selective separation of platinum, palladium and rhodium from Platinum Group Metals concentrates will be achieved by Deep Eutectic Solvents technology.

WP4: Optimization of the refining stage

As part of WP4, VITO will lead the optimization of the Microwave-assisted leaching technology for extracting ~ 95% of platinum-groups metals contained in concentrated autocatalysts, ~ 95% of palladium and gold and ~ 85% of silver from concentrated electronic waste, and ~ 85% of silver and lead from concentrated photovoltaic cells waste. Additionally, the Gas-diffusion electro-crystallization (GDEx) technology will be optimized aiming at recovery ~ 95% of platinum-groups metals, gold and silver from solutions coming from the previous technology.

WP5: Benchmarking with state-of-art refining processes

UNIVAQ will oversee WP5, which main aim is to create a benchmark between the state-of-art hydrometallurgical processes for recovery of precious metals and the PEACOC technology.

WP6: Engineering, construction and commissioning of the pre-commercial pilot

As part of WP4, 6TMIC will lead the construction of modular Microwave-assisted leaching and GDEx units in a stack configuration in order to treat flows in the 20-25 L/h range as a pre-commercial pilot. Moreover, such units will be integrated in a standard-sized container transportable by truck, whereas the automation system for will also be developed. Finally, both commissioning and start-up of the pre-commercial pilot will the conducted at 6TMIC’s facilities in blank operating conditions and at VITO and MONOLITHOS’s facilities in real operating conditions.

WP7: Validation of the pre-commercial pilot

MONOLITHOS will lead the normal operation mode of the pre-commercial pilot in order to demonstrate the production of 2 kg platinum-groups metals, 10 kg silver and 0.5-1.0 kg gold in one-week operation.

WP8: Valorization of the recovered precious metals and residual matrices into different applications

As leader of WP8, CRF will supervise the application of recycled platinum-groups metals for manufacturing, operating and testing up to 500 automotive catalysis, catalytic nanoparticles for electrochemical energy technologies, 3D-printed products and single metals. Moreover, this partner will oversee the near-zero waste strategy focused on recovering valuable materials for other industries.

WP9: Life-cycle assessment and life-cycle costing analysis

TECNALIA will lead WP9 that is designed to evaluate the environmental and economic sustainability of the PEACOC technologies. That will be assessed in both laboratory and industrial scale.

W10: Dissemination, communication and clustering

PNO Innovation will lead WP10 which main aim is to match the project results with market opportunities and make the project’s work widely known. It will promote the project results to variety of stakeholders and ensure uptake of the PEACOC technologies and products by the industry and decision makers. It will also ensure that PEACOC project is well connected with relevant EU, national and international projects, initiatives and networks.

W11: Stakeholder engagement and exploitation

ISL will be taking the lead of W11 in order to arrange and set up the post-project life of the project solutions. That would be achieved by creating a detailed uptake plan, market analysis and business plan dedicated for the PEACOC technologies.

This

project has received funding from the European Union’s

Horizon 2020 research and innovation programme under grant

agreement No 958302.

This

project has received funding from the European Union’s

Horizon 2020 research and innovation programme under grant

agreement No 958302.