Testing innovative technologies to optimise and upscale the concentration stage

During the first year of the project, University of Liege (ULiège) (BE) has been leading the optimisation and upscaling of the concentration stage in close collaboration with Delft University of Technology (TU Delft) (NL), processing three different waste streams (i.e., spent autocatalysts, low and mid-grade PCBAs and EoL PV panels) and targeting the following objectives:

- To concentrate gold (Au), silver (Ag) and palladium (Pd) from low/mid-grade Printed Circuit Board Assemblies (PCBAs) coming from Waste Electric and Electronic Equipment (WEEEs), through defining the best route combining NOVA, Ultra-fast sorting (UFS) and Magnetic Density Separation (MDS) technologies. Additionally, the concentration stage will aim the extraction of other valuable materials such as tin (Sn) and copper (Cu) for further valorisation

- To produce Platinum Group Metals (PGMs) – mainly platinum (Pt), palladium (Pd) and rhodium (Rh) – concentrates by separating the washcoat and ceramic support of enf-of-life (EoL) autocatalysts

- To produce Ag-concentrates from EoL PV panels using the Magnetic Density Separation (MDS) technology

Optimising NOVA technology to increase Precious Metals concentration from e-waste

NOVA technology at pilot scale

PCBAs (Printed Circuit Board Assemblies) can be found in all the modern products used daily, from cars and smartphones to household appliances. These PCBAs are notably rich in precious metals (PMs) and are therefore collected and sold to smelters. During various treatment steps of the collection and concentration activities they can lose their precious metals. In such cases, smelters lose interest in these “lower grade” PCBAs, which are further exported outside Europe. The ULiège NOVA process allows diversion from export by enabling extraction (process carried out in EU) of all remaining precious metals along with important societal metals such as tin and copper still contained in those “lower grade” PCBAs.

During this first year of the PEACOC project, ULiège adapted the NOVA technology on PCBAs coming from end-of-life TVs (CRT – Cathode-Ray Tube TVs and LCD – Liquid Crystal Display TVs). Precious metals, especially gold (Au), have been concentrated by separating the electronic components rich in PMs from PCB (containing only Cu, glass fibers, epoxy resin). The separation of electronic components reached the objective set as target, enabling to separate >90% of Au initially contained in PCBAs.

The mix of larger electronic components will further be processed by Ultra-Fast Sorting (UFS) to extract the ones carrying gold, which will enable to increase again the Au factor concentration.

Sn concentrate obtained after processing PCBAs using NOVA technology

Additionally, a Sn concentrate stream was obtained from the NOVA processing of PCBAs, that will be further valorised by TECNALIA (ES) within the PEACOC project.

Ongoing activities are currently addressing the economic evaluation of the NOVA process and the design study of the NOVA reactor, which will be purchased in the upcoming months

Testing the Ultra-Fast-Sorting (UFS) technology to extract PMs-rich electronic components

The Ultra-Fast Sorting (UFS) technology, initially proposed to extract PMs-rich electronic components, was tested by TU Delft to sort out specific electronic components such as capacitators rich in Pd, and integrated circuits rich in Au from the electronic components streams delivered by the NOVA process. The optimisation of the UFS is currently on-going. Additional to testing the UFS process, the research team from TU Delft is looking into alternative solutions which could be easily integrated with the magnetic density separation (MDS).

Improved MDS and UFS to concentrate PMs from electronic components and EoL PV panels

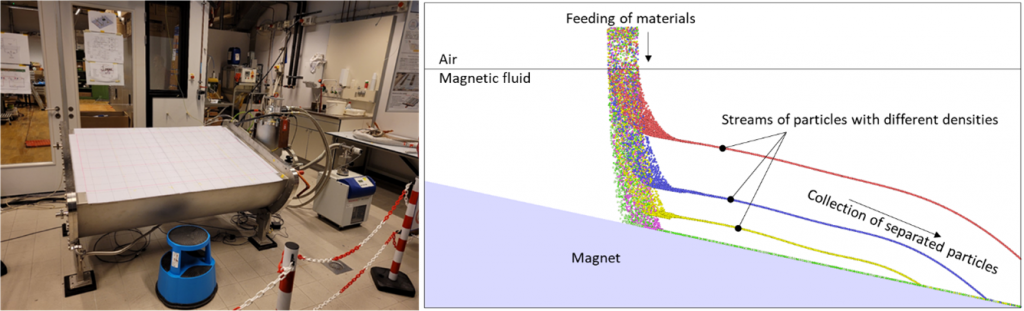

Based on the design proposed by Delft University of Technology (TU Delft), the MDS was optimised to produce the most appropriate streams for the PEACOC refining stage (i.e. PMs-concentrates from sorted electronic components rich in PMs by UFS followed by milling; Ag concentrates from PV metallic waste). The improved MDS will further be implemented within the experimental device. After running successful tests at laboratory scale, the operation will be upscaled to continuous running (pilot), where further experiments with the newly fabricated magnet and separation channel will be carried out.

A superconducting magnet operating at around 5 K and generating a magnetic field above 2 T is currently tested. This will help broaden the application of MDS in the aspect of material range. A series of experiments will be carried out on the effectiveness and stability of MDS (and magfluids) with the superconducting magnet.

Superconducting magnet and the simulation of the experimental MDS process

Optimised Flotation technology to treat different EoL autocatalysts

As a first phase, ULiège researchers have demonstrated the natural flotation of the washcoat – which is the active PGM-rich substance present in autocatalysts. During the follow-up stage, a two-stage process flowsheet will be implemented to enhance selectivity between the washcoat and its cordierite support element. According to first observations, the use of electrodynamic fragmentation prior to flotation emerges as more conclusive than standard ball mill comminution. Therefore, further experiments testing the coupling will be conducted to confirm initial assumptions.

This

project has received funding from the European Union’s

Horizon 2020 research and innovation programme under grant

agreement No 958302.

This

project has received funding from the European Union’s

Horizon 2020 research and innovation programme under grant

agreement No 958302.