Advancements in Microwave-assisted leaching and gas-diffusion electrocrystallisation

With the concentration stage reaching upscaling, the refining work package has diligently undergone similar activities. Involving a multidisciplinary team – research institutes and engineering companies, this step is dedicated to the development and optimisation of two cutting-edge technologies: microwave-assisted leaching (MWAL) and gas-diffusion electrocrystallisation (GDEX). The goal is to upscale these technologies from TRL 4 to TRL 7.

Microwave-assisted leaching

Researchers at VITO (BE) have been fine-tuning the MWAL at small scale, leveraging its versatility to treat different precious metals (PMs) waste streams. The initial development of the MWAL system at TRL 4 targeted the process optimisation through reduction of chemicals consumption and reaction times. The results of the experiments at small scale reported 100 % recovery rates for silver (Ag) and gold (Au) dissolution from waste electrical and electronic equipment (WEEE) samples.

Additional experiments were investigating MWAL’s efficiency for the extraction of Ag from photovoltaic (PV) metallic waste. Engaging additional pre-treatment operations such as the Magnetic Density Sorting (MDS) developed by TU Delft (NED) and the two-step leaching by University of L’Aquila (UNIVAQ) (ITA), researchers achieved complete Ag extraction.

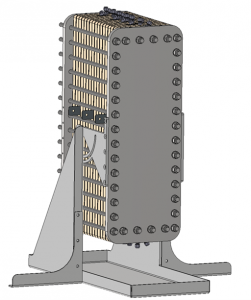

For the recovery of Ag from end-of-life (EoL) PV panels, researchers reported complete extraction within 30 minutes using a tailored leaching system. Similarly, nearly complete Au extraction was obtained using a lixiviant containing HCl, NaCl, and NaOCl. These results underscore the potential of MWAL to provide rapid and effective solutions for extracting precious metals from EoL products. Ongoing efforts are currently assigned to the upscaling process of MWAL to pilot scale (Technology Readiness Level TRL 7). CEINNMAT is currently constructing a pilot-scale microwave using innovative reactors for platinum group metals (PGM), Au and Ag extraction from different waste materials, using the reactions conditions provided by VITO. The system is built to provide a capacity of at least 50 L/h, tailored to handle specific conditions required for each EoL feedstocks with reduced energy use and improved efficiencies.

These advancements not only support the circular economy and urban mining but also provide solutions to alleviate the environmental impact of traditional mining and support the supply of crucial materials for European industries.

Gas-diffusion electrocrystallisation

In parallel, another team at VITO calibrated the operation of the gas-diffusion electrocrystallisation (GDEx) and refined the mechanisms and parameters to maximise metals recovery and direct nanoparticles synthesis. Initial tests of the GDEx process using leachates obtained by MWAL from spent autocatalysts showed near 100 % recovery efficiency in batch operation. Researchers validated the integrated process also on waste streams containing Au and Ag, issued from photovoltaic panels and printed circuit board assemblies, respectively, attaining 100 % recovery rates.

These past months developing the lab-scale process allowed researchers to gain a clear understanding of the integrated MWAL followed by GDEx and electrode design. With this important milestone reaching completion, the project shifts towards the next phase: testing the upscaled GDEx unit in continuous operation mode.

The first trials, featuring an upscaled 2-cell stack configuration, have already achieved a promising selectivity of >95 % for the PGMs recovered from industrial streams from Johnson Matthey. Researchers at VITO are already setting-up a 6-cell configuration and building the overall balance of plant for GDEx, while 6TMIC is developing the automation hardware and software that will support the operation of the process. With these advances, the consortium will soon be able to demonstrate the PEACOC process for the production of 2 kg platinum-groups metals, 10 kg silver and 0.5-1.0 kg gold in one-week operation.

This

project has received funding from the European Union’s

Horizon 2020 research and innovation programme under grant

agreement No 958302.

This

project has received funding from the European Union’s

Horizon 2020 research and innovation programme under grant

agreement No 958302.