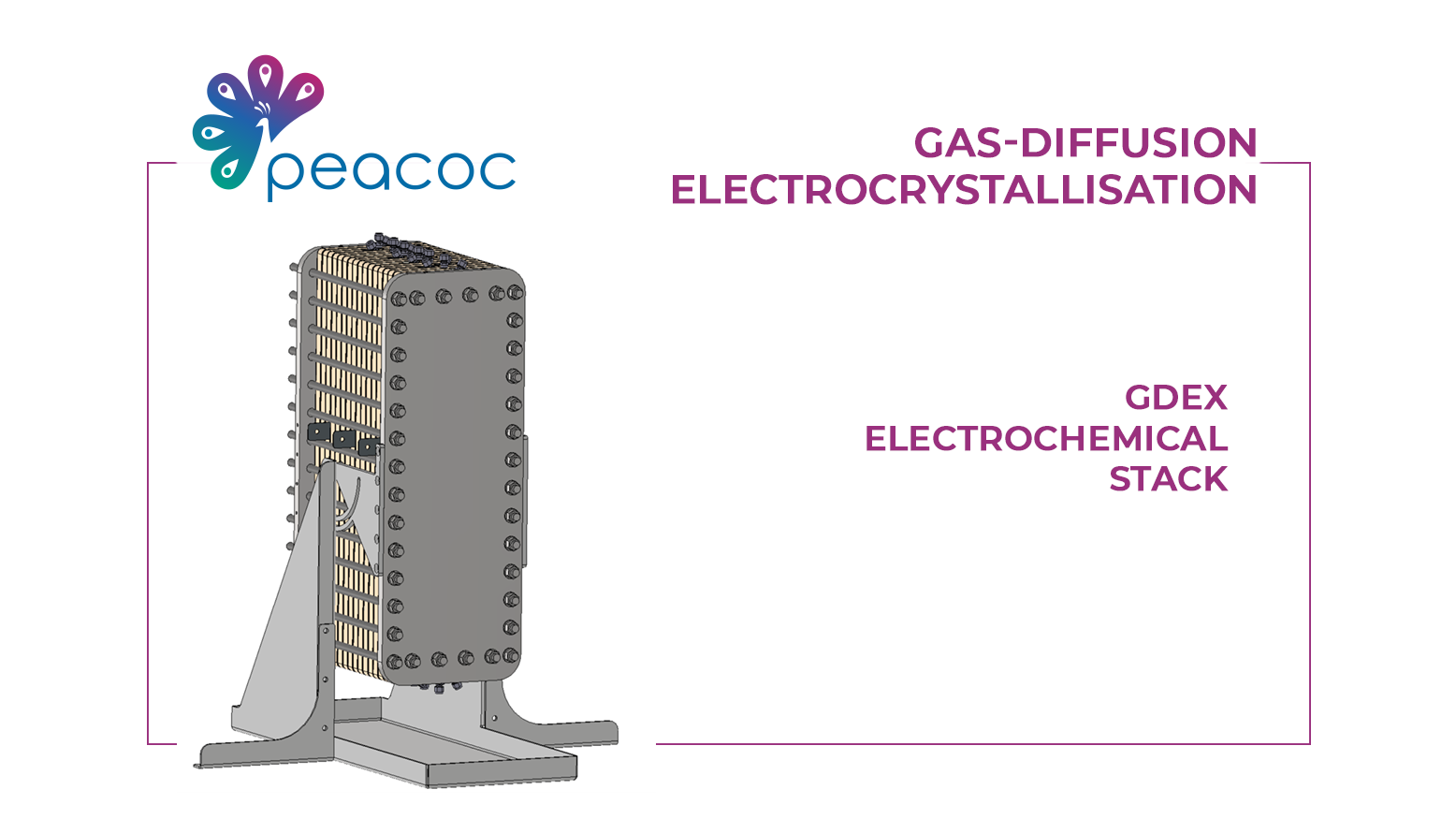

Gas-Diffusion Electrocrystallisation

Gas-diffusion electrocrystallisation (GDEx) is an electrochemical technology that has been developed at VITO in Belgium. It serves as a refining stage in the PEACOC project, aiming to recover Precious Metals (PMs) from End of Life (EoL) products. GDEx enables the production of Precious Metal (PM) nanoparticles in either metallic or (hydr)oxide form, depending on the specific operating conditions.

After successfully testing GDEx with process streams from Johnson Matthey and PMs leachates generated by other project partners, efforts have shifted now towards scaling up the process. The team is currently finalising the basic and conceptual engineering, with particular attention on the design of the stack reactor and peripherals. This design aims to accommodate the desired flow rates and recoveries targeted by the PEACOC project. To reach these objectives, VITO has developed a stack of 6 cells with an optimised flow channel configuration. The GDEx Unit, which includes the GDEx stack, will be semi-automated to ensure the targeted recoveries and final product quality. Several challenges were encountered, including the appropriate selection of materials capable of withstanding highly corrosive streams (i.e., acidic leachates). Additionally, it was crucial to design the flow channels in the stack to optimise the distribution of flow velocity. Consequently, this ensures a homogeneous current density distribution on the electrode, minimising dead volumes or the potential accumulation/deposition of the formed PM nanoparticles.

The construction and assembly of the stack and the GDEx Unit will follow in the coming months. Subsequently, it will undergo testing at VITO in continuous operation with Johnson Matthey streams. The testing phase is crucial prior to integrating the GDEx Unit with the rest of the upscaled PEACOC process at the Monolithos facility in Greece. At Monolithos, the integrated pilot will be operated to meet the PEACOC Key Performance Indicators (KPIs), including the following weekly production targets: 2 kg of Platinum Group Metals (PGMs), 10 kg of silver (Ag), and 0.5-1 kg of gold (Au) from spent automotive catalysts, photovoltaic panels (PV), respectively Waste from Electrical and Electronic Equipment (WEEEs).

The accomplishments of this work are credited to the dedicated engineering team at VITO, which includes Diane Van Houtven, Pete Grahame Fawcus, Jan Courtois, Bart Molenberghs, Rob Muijshondt, and Jef Verheyden. In addition, the scientific team consisting of Luis F. Leon-Fernandez, Ramin Rabani, and Xochitl Dominguez-Benetton has played a pivotal role in these achievements.

GDEx electrochemical stack

This

project has received funding from the European Union’s

Horizon 2020 research and innovation programme under grant

agreement No 958302.

This

project has received funding from the European Union’s

Horizon 2020 research and innovation programme under grant

agreement No 958302.