Review cluster workshop “Recycling and production of highly efficient catalysts for different applications”

The Raw Materials Week opened with Monday’s cluster workshop, organised as satellite event, bringing together six EU-funded projects: FIREFLY, PEACOC, NEO-CYCLE, ALCHEMHY, SUSTAINCELL and HIGHLANDER, addressing sustainable catalyst production, a quiet, yet critical challenge for Europe’s industrial future.

Catalysts may not make today’s headlines, but they drive 90% of chemical processes and support 60% of industrial products. Without them, ambitions for clean energy, advanced manufacturing and circularity would stall.

Projects and stakeholders present at the workshop discussed the scientific innovations as well as the urgency of collaboration, which allowed them to identify overlaps and gaps and explore the development of an innovation ecosystem.

PEACOC, co-presented by Elisabet Andres Garcia (TECNALIA) and Anastasia Maria Moschovi (MONOLITHOS), showcased its three pilot units recovering platinum, palladium, rhodium and other precious metals from end-of-life autocatalysts, photovoltaic panels and electronics. The PEACOC pilots have recently run successful tests on automotive catalysts, achieving over 90% metal recovery rates. Researchers at MONOLITHOS are currently contemplating the possibility to extend the process to other streams, such as lithium-ion batteries and fuel cells.

FIREFLY introduced its electrochemical toolbox powered by renewables and guided by AI, aiming to turn industrial waste into high-purity electrocatalysts. The project coordinator, Savitha Thayumanasundaram (VITO), explained how recovered metals are used to produce electrocatalysts for demo cases such as ammonia and hydrogen peroxide production, with cradle-to-cradle approaches validated and benchmarking against state-of-the-art recycling technologies showing high efficiency and automation potential. Sustainability assessments indicate lower environmental impact compared to primary mining, and techno-economic analyses highlight the importance of feedstock pricing.

NEO-CYCLE focused on upcycling rare-earth magnets from e-waste for pharmaceutical and polymer applications using solid-state chlorination and electrochemical purification. Early results, presented by Hubert Ronduda from Warsaw University of Technology, show successful catalyst development using both high-purity and recycled salts, with strategies to manage impurities such as nickel and cobalt, and validation of catalyst performance in ammonia synthesis and decomposition.

Download NEOCYCLE presentation

HIGHLANDER presentation, clearly leveraging Johnson Matthey’s experience as a major secondary refiner, enriched the discussion with industry statistics about recycling, showing it is driven by value and volume, with high-value components like PFAS and PGM encouraging recovery, and the need for regulatory support to prevent leakage of critical materials such as iridium.

Marie-Laure Fontaine, Research Manager at SINTEF Industry, representing SUSTAINCELL, presented examples of developed catalysts, such as nickel-based materials for low temperature fuel cells, showing promising performance compared to literature benchmarks.

Download SUSTAINCELL presentation

Blanca Arias Serrano, Senior Researcher in Solid Oxide Cells at Iberian Centre for Research in Energy Storage, presented the ALCHEMHY project, which targets the decarbonisation of ammonia and methanol production through four electrified, cost-effective pathways, advanced catalysis, and digital twins, with pilots to be validated at TRL 5-6.

Download ALCHEMHY presentation

Technical discussions ranged from impurity management in recycled magnets to the selectivity of microwave-assisted leaching for precious metal extraction. The additional challenge of managing the plastic waste in electronic recycling spurred from the technical discussions, along with the potential for using palladium in fuel cells and electrolysers and strategies for managing residual nickel and cobalt in recycled streams.

Beyond its role as workshop facilitator, PNO Innovation delivered a comprehensive presentation of EU funding opportunities under Horizon Europe, the EIC Accelerator and LIFE, with details on relevant calls, TRL levels and focus areas, such as advanced materials, recycling and bio-based innovations.

Scrutinising interest in future cluster activities

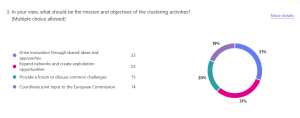

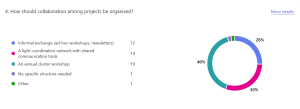

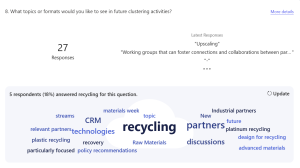

These funding mechanisms were echoed by calls for clustering beyond project coordinators. The interactive survey closing the session showed growing interest in annual workshops around the topic of catalysts and light coordination networks, with future topics including recycling, CRM technologies and balanced coverage of research and innovation.

- Support for continued clustering activities: the majority of respondents (19 out of 28) vote in favour of continuing clustering activities regularly, while 24 out of 28 support creating a joint EU cluster with a shared online platform.

- Top priorities: networking and innovation: the most valued objectives for clustering are expanding networks, creating exploitation opportunities and driving innovation through shared ideas.

- Collaboration and visibility approaches: public opinion suggested annual workshops and extending invitations to more project partners to present as preferred collaboration platforms to turn activities more visible and inclusive.

The catalyst recycling workshop attracted a well-balanced audience, marking an attendance rate of approx. 55%. Research institutes and academia formed the backbone of discussions, representing roughly 60% of attendees, while industry accounted for about 25% and consultancies and policy stakeholder for the remaining 15%. This mix of sectors reflects the workshop’s purpose: connecting scientific innovation with industrial application and regulatory frameworks. The strong presence of research highlights Europe’s depth in technical expertise, while industry participation confirms growing interest in scaling up catalyst recovery technologies.

- Materials for Catalysts cluster workshop – opening

- Materials for Catalysts cluster workshop – PEACOC presentation

- Materials for Catalysts cluster workshop – PEACOC pilot

- Materials for Catalysts cluster workshop – FIREFLY

- Materials for Catalysts cluster workshop – NEO-CYCLE

- Materials for Catalysts cluster workshop – HYGHLANDER

- Materials for Catalysts cluster workshop – Funding schemes

This

project has received funding from the European Union’s

Horizon 2020 research and innovation programme under grant

agreement No 958302.

This

project has received funding from the European Union’s

Horizon 2020 research and innovation programme under grant

agreement No 958302.